Generation School

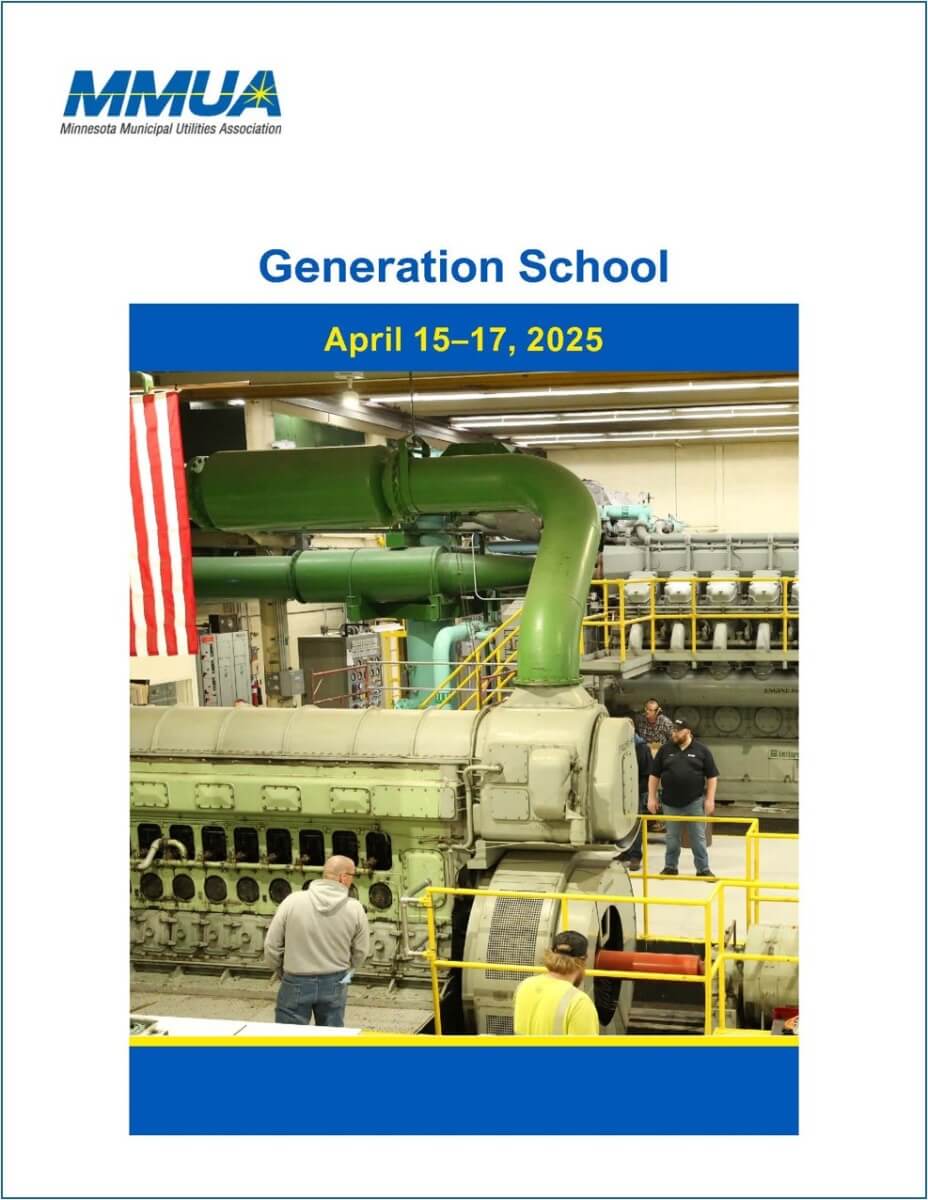

With a mix of classroom and hands-on learning, Generation School appeals to all learning styles and all levels of experience. In the classroom, attendees will learn about operations inspection testing, maintenance best practices, reporting, and more. Attendees work and learn with real systems, seeing and feeling what the seasoned instructors explain in real time, while working on engine sets that include Caterpillar, Cooper/Enterprise, and Fairbanks Morse.

The Generation School is an annual event facilitated at several locations. To learn more about the program and the topics covered, click on the event brochure.

Event Details

Date:

2026 date TBA

Locations:

TBA